celotec Folienbestrahlung

Technische Folien benötigen oftmals besondere Eigenschaften, um in ihrer Anwendung effizient, nutzbar und beständig zu sein. Mit celotec Elektronen-Bestrahlung wird möglich, was durch Rezeptänderungen in der Folienproduktion oftmals nur schwer oder gar nicht erreicht werden kann: eine Veränderung der Folieneigenschaft, z.B. in punkto Hitzebeständigkeit, Handreißbarkeit, Sterilität oder Bio-Abbaubarkeit.

Die Produktionsanlage von celotec bietet beste Möglichkeiten, Kunststofffolien im industriellen Maßstab mit Elektronenstrahlen zu behandeln.

Welche Kunststoffe können mit Elektronenstrahlen behandelt werden?

- Polypropylen (PP)

- Fluorpolymere (PVF, PVDF)

- Ethylen Copolymere (EVA, Surlyn)

- Nylon (PA6, PA6-6)

- Polyethylen (HDPE, LDPE, UHMW-PE)

- Polyacrylate

- Polyvinylchlorid (PVC)

- Synthesekautschuk (EPR, SBR)

- Naturkautschuk

- Polyurethan

- Silicon- und Nitrilkautschuk

- Polybuthylenterephtalate (PBT)

- EPDM

- Polybutadien

Welche Eigenschaft soll Ihre Folie haben?

In unserer ESH-Anlage treffen beschleunigte Elektronen auf die Moleküle des Werkstoffs und brechen deren Bindung auf. Auf dieser Basis werden chemische Reaktionen ausgelöst, die zu veränderten Eigenschaften führen. Wir zeigen Ihnen, wie Sie sich Prozesse wie die Elektronenstrahlvernetzung zunutze machen können:

Was ermöglicht die hochfunktionale ESH-Anlage von celotec?

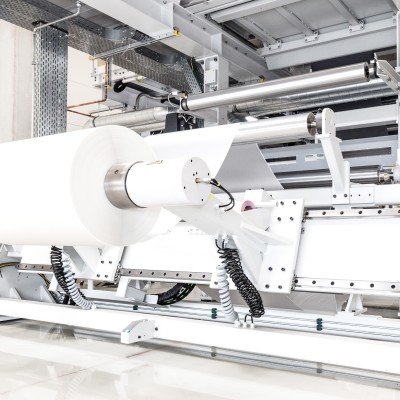

Der Elektronenstrahler von celotec ist Teil einer großen Rolle-zu-Rolle-Beschichtungsanlage. Diese Anlage bietet eine Vielzahl an Möglichkeiten zur Bestrahlung und Beschichtung von bahnförmigen Medien. Des Weiteren besitzt die Anlage ein optisches Bahninspektionssystem und die Möglichkeit eines Inline-Randkantenschnitts. Im Beschichtungsteil der Anlage gibt es neben dem Lackauftragswerk auch UV-Einheiten und Excimer-Lampen.

Zur Vorbehandlung von Folien sind eine Relaxier-Station, eine Bahnreinigung und eine Corona-Einheit verbaut. Bei Bedarf können an einem separaten Rollenschneider Folien in Quer- und Längsrichtung geschnitten und umgewickelt werden.

Neben der Bestrahlung bieten wir Ihnen beste Möglichkeiten, Folien und Papiere mit strahlenhärtenden Lacken zu beschichten. Dabei stehen unterschiedliche Lacksysteme in transparent und pigmentiert für verschiedenste Anwendungsgebiete zur Verfügung. Genauso können aber auch kundenspezifische Lacke gemeinsam entwickelt und verarbeitet werden, um Folien bestimmte technische Eigenschaften oder einen dekorativen Charakter zu verleihen.

Wie ist der Ablauf vom Labormuster zur optimalen Folie?

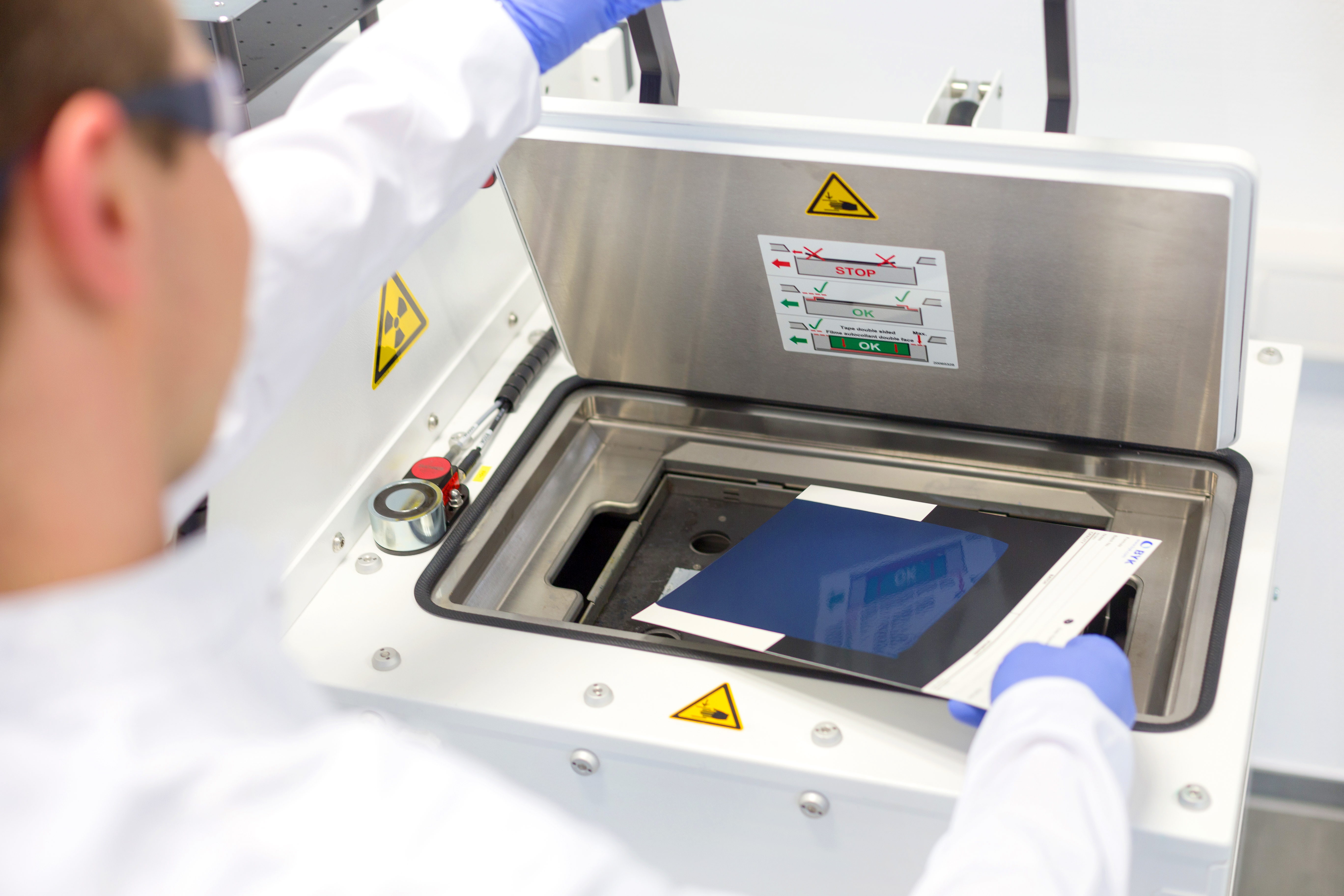

Sie möchten Ihre Kunststofffolie durch celotec Elektronen-Bestrahlung verbessern? Mit celotec und celolab kein Problem! Denn auch in unserem hervorragend ausgestatteten Oberflächenlabor steht eine Bestrahlungseinheit zur Verfügung, mit deren Hilfe grundlegende Versuche durchgeführt werden können.

Wir führen Sie durch einen effizienten und transparenten Prozess von Ihrer Anfrage bis zum optimalen Produkt.